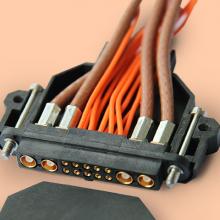

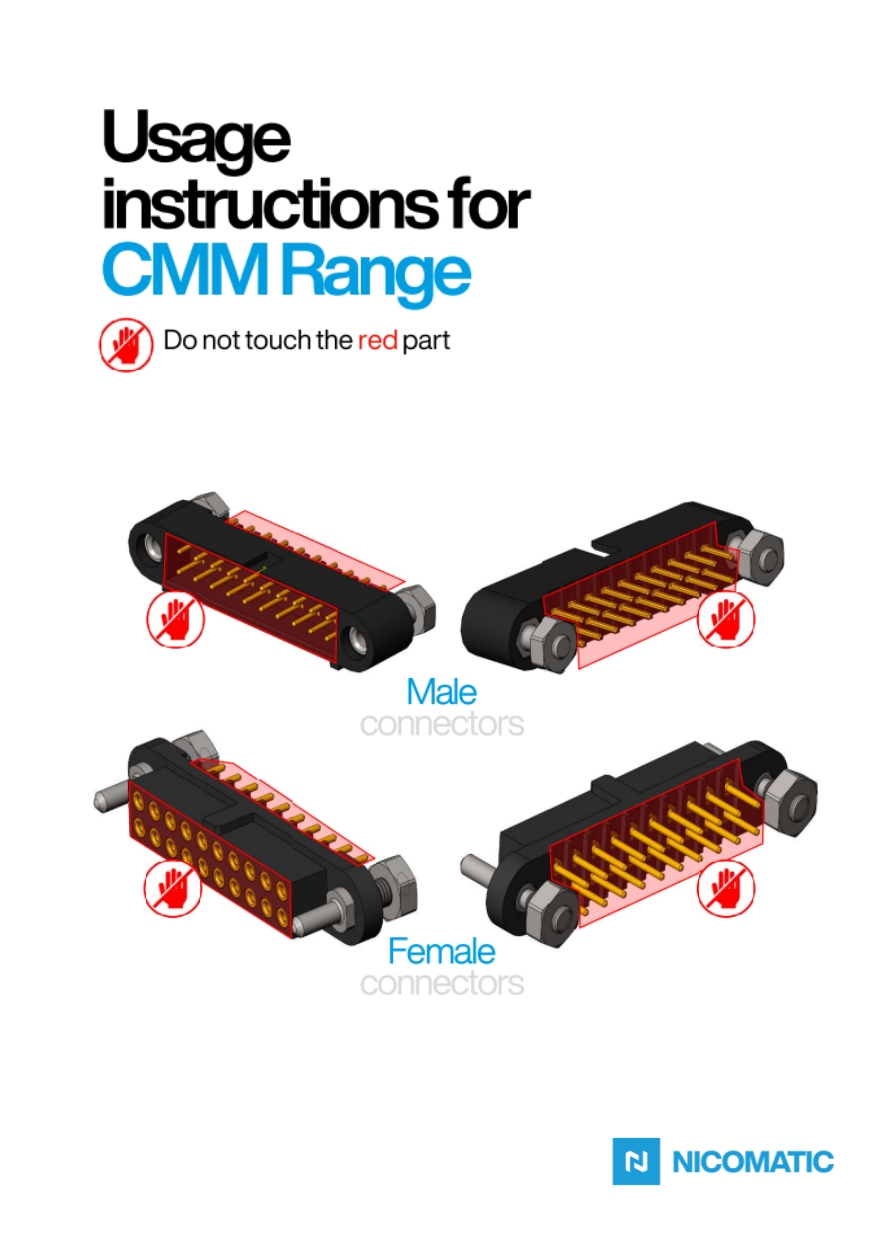

CMM connectors are designed to meet or exceed electrical & mechanical performances of MIL-DTL-55302F and BS-9525-F0033 standards. This modular connector allows more than 20 million arrangements.

Main features:

- Extreme modularity (Signal, power and coaxial contacts, from 1 to 3 rows, up to 120 pins)

- 2mm pitch

- Board-to-board, board-to-wire, wire-to-wire configurations

- Space-saving up to 60%, weight saving up to 50% compared to other existing rectangular micro-connectors with the same functionalities

- Robustness with PPS material: no humidity absorption, oxygen-free, radiation resistance and solvent resistance

- Temperature cycling between -60°C and + 260°C

- Highly resistant to vibrations and shocks

- Various and numerous fixing hardware

- Lead time from 1 week, no MOQ

- Online services iOS/Android for designers (automatic part numbering system, automatic 2D and 3D drawings)