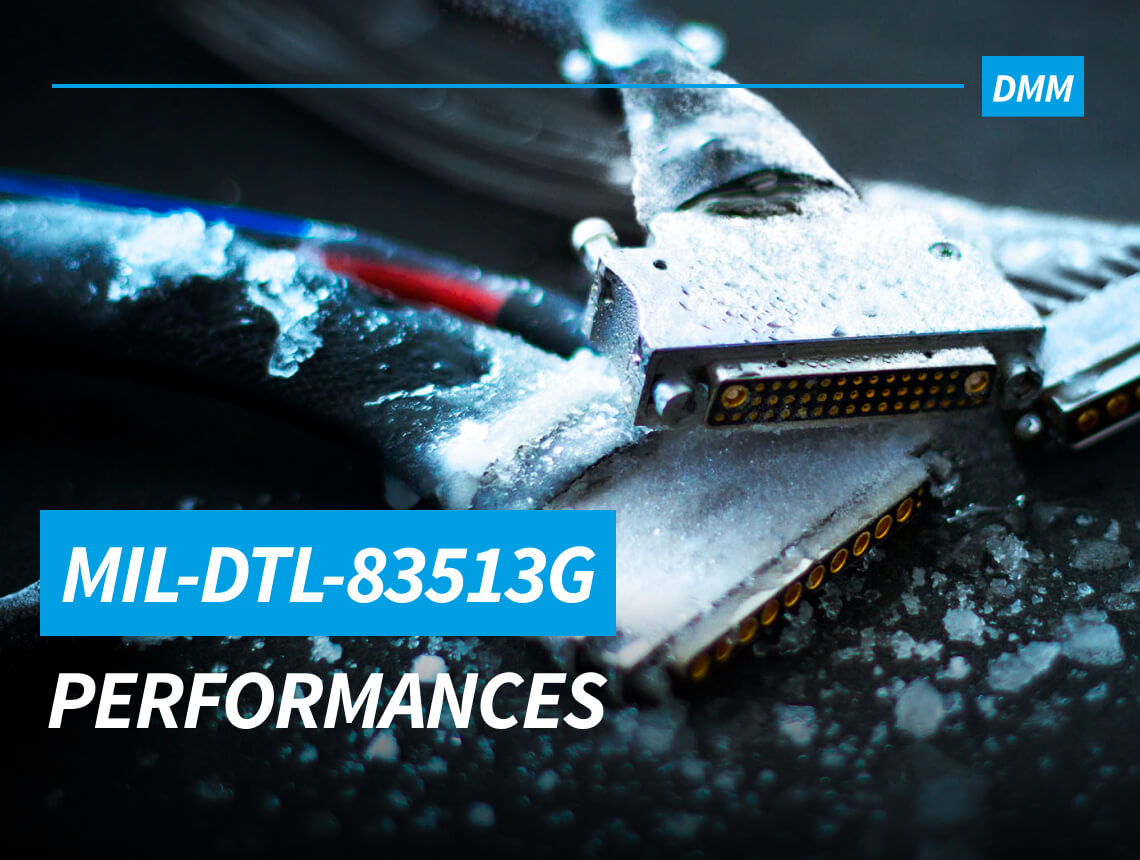

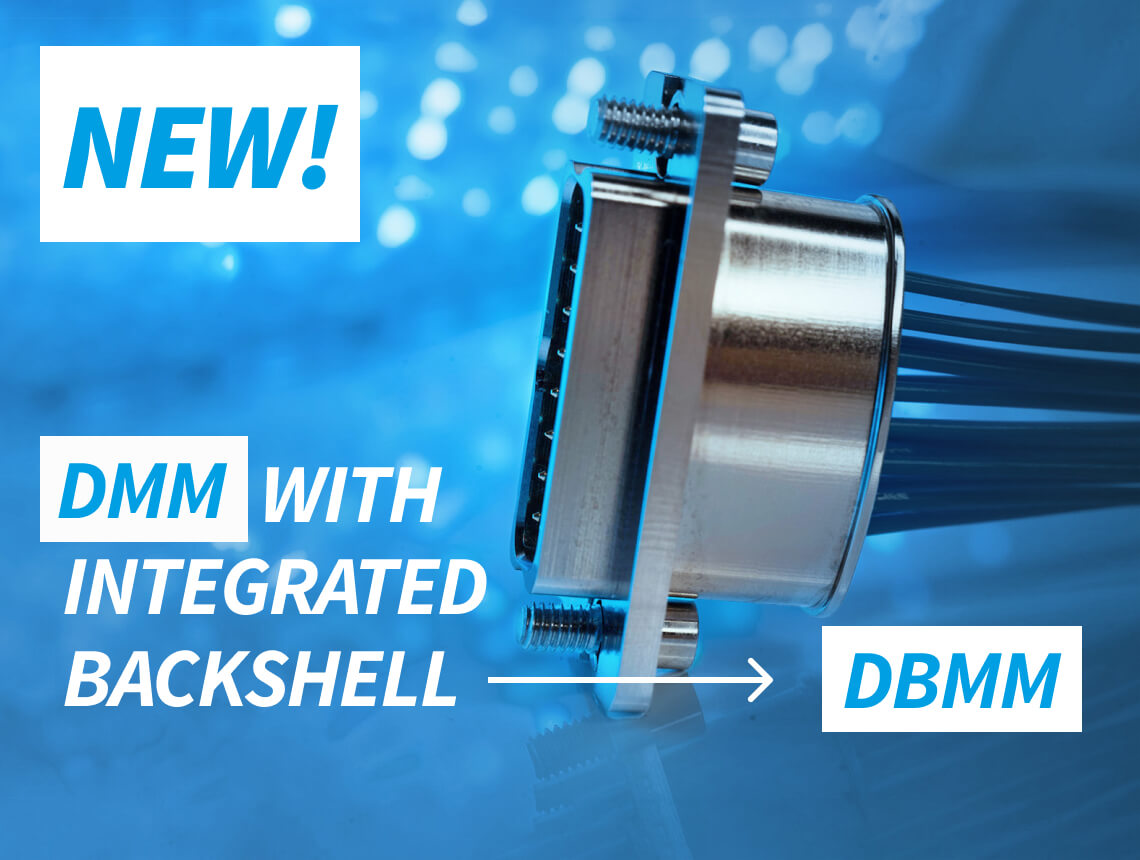

DMM rugged connectors comply with MIL-DTL-83513G performances and enable a wide choice of arrangements compared to other mil-spec connectors like Micro-d or Sub-d. They allow space-saving, electromagnetic & mechanical protection. Moreover, you can use one-piece or two-piece backshells for 360° shielding and protection of your cable interconnection. You can use DMM with Flange for better shielding continuity when mounting on a panel or without Flange as a low-profile solution.

Features :

- 4 weeks lead time, MOQ = 1 part

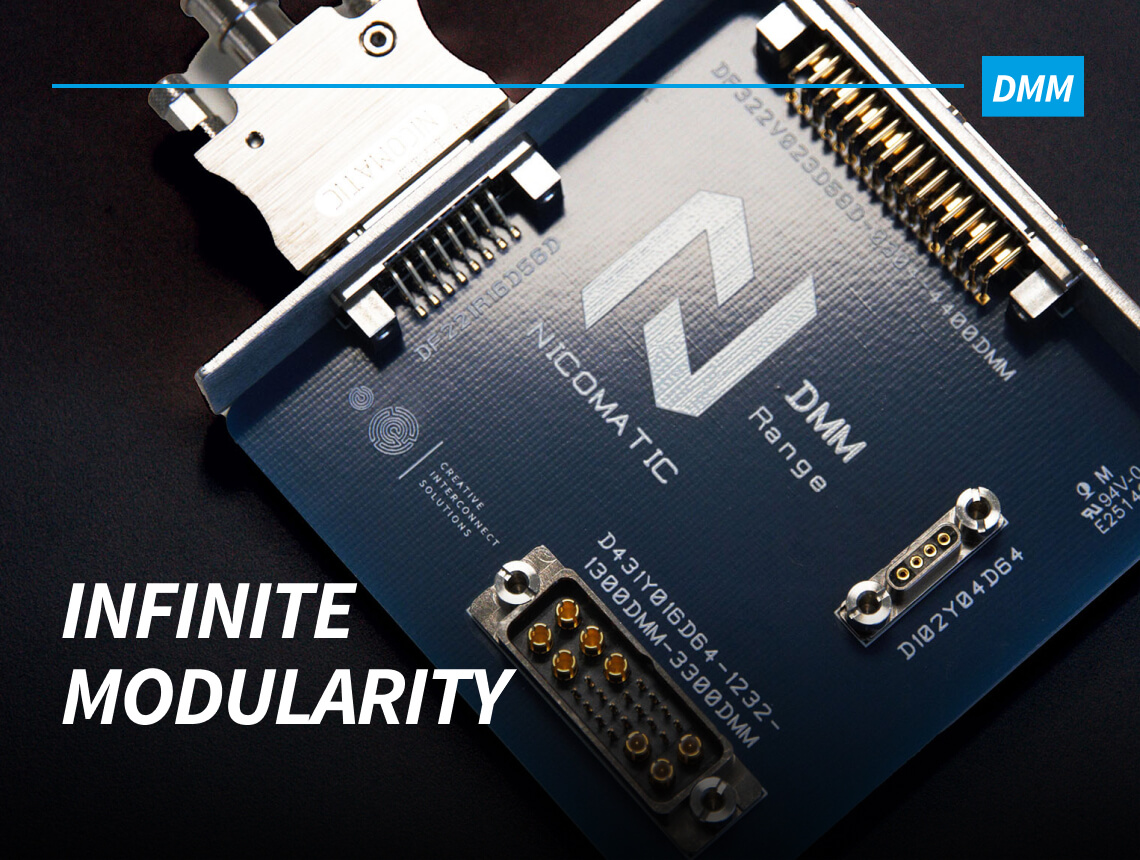

- High modularity: contacts Signal ( LF), Power (HP), and Coax (HF) up to 10M arrangements

- Board to board, board to wire, wire to wire, panel mount (1 to 4 rows of contacts)

- Miniaturisation: 2mm pitch, low profile

- Ruggedized with aluminium alloy 6061

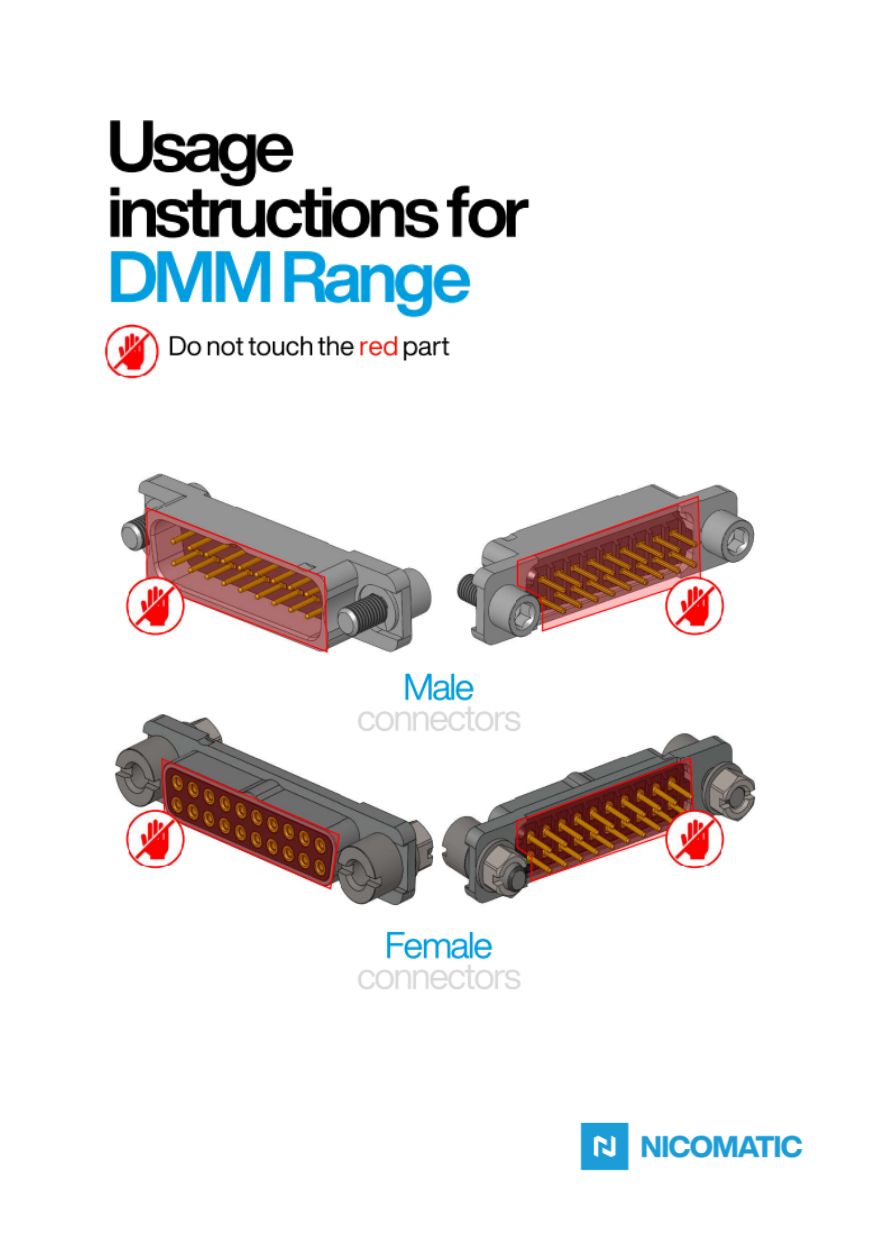

- Easy maintenance thanks to dismountable contacts